Lidar: How to get OEM orders with diffractive optics

By Alex Coney

Recent industry deals show what automotive lidar companies need to win an OEM order: a credible path to low-cost, compact products. The sensor optics and unconventional optical designs can offer that much-needed edge over competitors, says Alex Coney.

Several lidar companies have recently taken big steps towards having their technology incorporated in series production cars. Volvo is now collaborating with Luminar to combine the company’s lidar with vehicle control systems and create a highway pilot feature, to be available in 2022, and BMW has chosen Innoviz’ lidar for its iNext product range for launch next year.

These orders from BMW and Volvo are nods to the control companies like Luminar and Innoviz have over the key technologies behind the impressive performance of their products. They are IP-rich and not reliant on suppliers for their most important components – they are able to offer the complete package.

For other lidar developers with promising technology, the key to winning OEM orders is to show a credible path to low-cost, compact lidar products through control of all key technologies within the product.

One such technology that has a huge bearing not only on the performance parameters by which lidar sensors are judged (such as range, resolution, field of view) but also on the size and cost of the product are the optics.

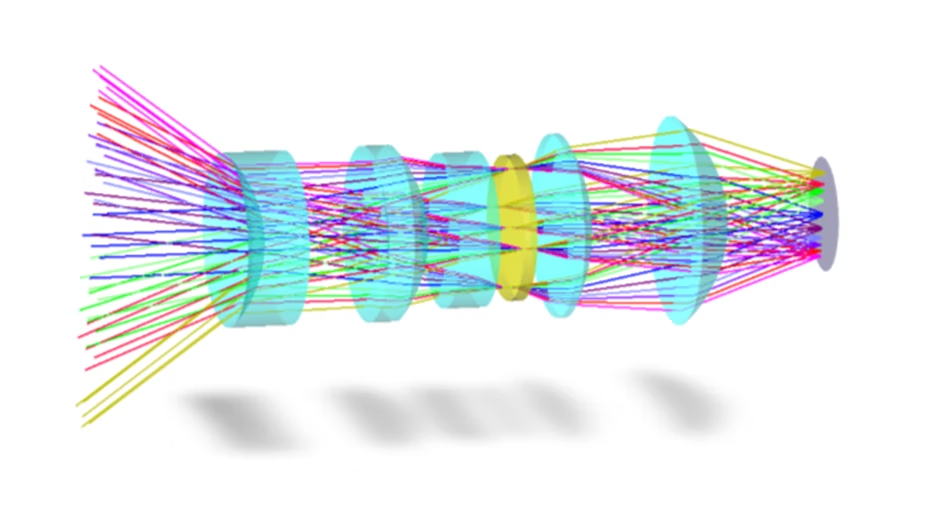

High performance optical systems are complex with many carefully aligned elements (Figure 1), meaning that the optics can easily account for more than 50% of the cost and size of the entire A-sample prototype. By taking advantage of unconventional optical designs, lidar companies can arrive at a lower cost B-sample that is much more attractive to automotive OEMs.

In this blog, we discuss:

• The limitations of refractive optics

• Diffractive optics as an alternative approach to creating compact lidar system designs

• Misconceptions about diffractive optical designs

• The journey from A-samples to B-samples and beyond

The limitations of refractive optics

Most lidar systems use traditional refractive optics – glass or polymer lenses which refract (bend) light – to collect light over a wide range of angles and focus this down onto a small detector. In addition, lidar receivers incorporate very precise optical filters to separate very low optical signals from high levels of background noise – such as sunlight. The performance of these filters is strongly dependent on the angle of the incident light, which adds further constraints on the system.

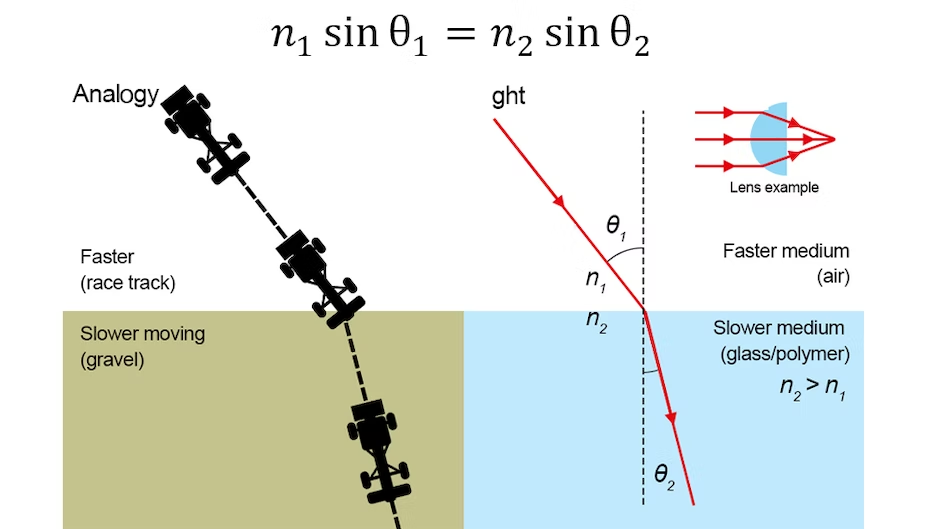

The challenges come when you try to dramatically reduce the size and complexity of a refractive optical system. To make an optical system as small as possible, we want to bend the light as much as possible with each optic in the system so we can use fewer lenses and reduce the spacing between optics. Here, we run into fundamental physical constraints because of a 1000-year-old physical relation known as Snell’s law of refraction (Figure 2).

Light changes direction in a medium of differing refractive index due to a change in speed of the light – similar to how a car turns when one wheel comes into contact with a rough (slower) surface.

Under Snell’s law, to make a strong lens with short focal length (large θ_2) we have two parameters which we can play with.

One is the angle at which incident light hits the lens (θ_1), that is by working with high curvature surfaces. The natural limit to this approach is a hemisphere. Increasing the curvature of lens surfaces can reduce the size of the overall optical system but drastically increases the thickness of the individual optics and with it the cost and weight of the optics. Also, image quality can degrade quickly with curvature angle, unless this is ‘undone’ somewhere else in the optical design.

Another approach to reduce focal lengths is to make the lens out of a high refractive index material (maximising n_2). This is common in opthalmics but is also limited. Most optical systems use glass or polymers, which have refractive indices that are only 40-60% greater than air. To do much better than this requires expensive lab grown crystals or exotic compounds both of which are out of the price range of mass produced automotive lidar.

To design effective lidar optics that go beyond the constraints of Snell’s law, unconventional techniques are required.

Diffractive optics as an alternative approach to creating compact lidar system designs

Diffractive optics work by a different physical principle to refractive optics and are not constrained by Snell’s law, offering an alternative approach to creating lidar optics.

Diffractive optics exploit the wave properties of light by creating interference between adjacent rays causing a change in direction, which can be used to ‘focus’ the incident light.

Diffractive optical elements are typically created by a modulated surface relief pattern, creating an optical element akin to a diffraction grating. The specifics of the modulation allows the light diffraction angles to be tightly controlled, directing the light to where it’s required.

The challenge when designing diffractive optical elements has historically been the design and manufacture of complex mathematical surfaces to high enough precision to achieve efficient diffraction. Modern computation and microfabrication techniques have addressed much of this, and now diffractives (and their cousin, the Fresnel lens) are commonly used in space-constrained optical systems such as VR headsets.

The circular symmetry found in lidar optics simplifies the design and manufacture of a diffractive lens. With the beam shape at the focal plane being a Fourier transform of the diffractive surface profile, the symmetry reduces the complexity of the mathematics needed to describe the system.

Fundamentally, diffractive optics offer shorter focal lengths and reduced thickness optical elements resulting in smaller, cheaper products. Diffractive optics also work best with monochromatic light, which has limited their applications in multi-colour imaging but makes them ideal for lidar systems. Moreover, the optical filters used in lidar work by a similar wave interference principle to diffractive optics and therefore have similar requirements for the input light. This creates an opportunity to combine them, leading to a reduction in size and part count.

Beyond these fundamental advantages, diffractive elements increase design flexibility in the development of lidar systems. Diffractive elements and refractive lenses can be combined to create so-called hybrid lenses, with the diffractive surface modulation either on the curved or the planar surface. Such optics can offer significant improvement in the performance of a single lens.

The strengths of diffractive and refractive optical elements are also complementary. A refractive lens can collect light from a wider range of incident angles and feed them into a diffractive optic. This creates an opportunity to create wide angle systems, such as those in automotive lidar sensors, within a reduced space envelope.

Misconceptions about diffractive optical designs

It’s often said that diffractive optics are more costly than a refractive equivalent, but this does not hold true for automotive lidar. It is true that there are fewer suppliers for low volume manufacture, which can increase the cost of prototyping. But at the volumes of mass-production cars, the scales can tip in favour of diffractive optics.

High volume production is likely to utilise injection moulding techniques similar to refractive lenses. The cost of injection moulded parts consists of the tooling cost to set up the process and the cost of the material which is moulded. Once volumes reach the mid-10,000s the material cost starts to dominate, at which point diffractive optics become less expensive because of their reduced volume relative to refractive optics.

Another common concern about diffractive lenses is their efficiency and stray light. For diffractive optical elements, diffraction efficiency is the fraction of the incident light that makes it into the desired first “focussed” order. Effects such as zero order transmission (unchanged light), surface imperfections, or scattering from sharp edges of the surface modulation can reduce this efficiency.

However, diffractive optical elements can be designed to achieve very high efficiencies: up to 99.5 % diffraction efficiency is achievable in our experience, which compares favourably with refractives and is more than enough to enhance the performance of a lidar system and create an attractive package for the OEM.

The journey from A-samples to B-samples and beyond

Job number one for any lidar developer is to get to a functional prototype, or A-sample, to demonstrate the viability of their approach and refractive designs are a great place to start. It is not always necessary to design the system in-house as many contract optical manufacturers offer design services and generally do an excellent job with refractive designs.

However, by the standards of these companies, lidar volumes are still relatively low. This makes it uneconomical for them to spend significant time and effort on improvements to system size and simplicity. Nevertheless, this can be a quick way to get to an MVP and demonstrate the technology.

Recent industry deals show that successful B-samples need to be closer to the low-cost compact sensors that OEMs expect to integrate into their vehicles. Often size and cost savings can be made by careful optimisation of the refractive system, but typically this must be done in-house and gets trickier as you approach the fundamental limits of refractives. Working beyond this limit requires a fresh approach; one which is offered by diffractive optics.

Combining refractive optics with their diffractive counterparts will enable lidar companies to hit the specifications needed for future production vehicles. Refractive lenses alone do not offer the design flexibility needed to optimise range, field of view and resolution, whilst minimising space and driving cost down. An unconventional approach to lidar optics is needed to achieve the next level of performance.

TTP has developed diffractive optics for a range of applications for over 20 years. We are now working with lidar companies to redesign their optical systems using unconventional techniques such as diffractive optics and anamorphic designs to achieve high performance within a limited space envelope at a low price point.